Why does a three-phase motor have only three wires?

The so-called three live wires are actually three phase wires. If you want to know why the electric motor (three-phase) needs to be connected to three phase wires, it is necessary to understand the relationship between these three phase wires and talk about the basic parameters.

The voltage between any two phase lines is called line voltage, which is 380V. The voltage of any phase line to the neutral line (or to the ground) is called phase voltage, which is 220v. Three-phase motors use three phase lines, so the rated voltage of three-phase motors is 380V. This is voltage. Let's talk about the phase relationship. Since the three-phase generator windings are placed according to a certain rule, the electricity generated has certain characteristics according to this rule, that is, the phase difference is 120 degrees. Maybe you don't quite understand the phase. If the three of them alternately reach the maximum value (AC power has peaks and troughs, unlike DC power, which reaches the maximum value when it reaches the peak), there is a certain order in which of the three reaches the maximum value first, and this order depends on the order in which the generator windings are placed!

Generally speaking, the U phase reaches its maximum first, then the V phase reaches its maximum, then the W phase reaches its maximum, and then the U phase reaches its maximum, and so on! That's all about three-phase electricity! Let's talk about motors. There are AC motors and DC motors. AC can be divided into single-phase and three-phase. What we are talking about now is a three-phase AC (asynchronous or synchronous) motor. The reason why a three-phase AC motor can rotate is because the three-phase electrical phases are 120 degrees apart from each other, or in other words, the three-phase line alternates to reach the maximum value!

If there are 3 live wires, just arrange the 3 live wires and connect them to the motor. If it is reversed, just swap 2 live wires. If there is 1 live, 1 neutral, and 1 ground, connect the live wire to the common terminal, the neutral wire to the capacitor terminal, and the ground wire to the metal casing of the motor.

How to connect a three-phase motor with only three wires

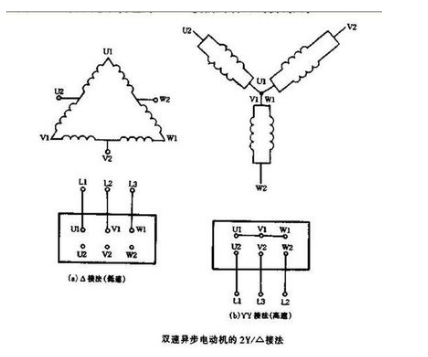

Three-phase motors usually need to be connected to three power lines, namely phase A, phase B and phase C. When wiring, the three coils of the motor need to be connected to the three phases of the power supply, usually using two wiring methods: star and triangle.

Star connection: Select any two wires from the three-phase power line and connect them together to form the neutral line N of the power supply. The remaining line is called line L. Connect one terminal of the three coils of the motor to the neutral line N of the power supply, and the other terminal to the power lines L, L+B, and L+C respectively.

Delta connection: Connect the three phase wires of the power supply to the three coils of the motor in sequence to form a closed loop.

It should be noted that the phase sequence of the power supply must be determined before wiring to avoid incorrect wiring that may cause the motor to malfunction or be damaged. During the wiring process, safety operating procedures should be followed to ensure the safety of the workplace and personnel. At the same time, it is recommended to ask a professional electrical engineer or motor technician to perform wiring and inspection to ensure the correctness and safety of the wiring.

There are two wiring modes for three-phase motors:

1. The first type is the star (Y) connection method. The head or tail end of the three-phase stator winding inside the motor is connected, and the other three phases are respectively fed with UVW three-phase alternating current for operation. It is suitable for three-phase asynchronous induction motors of 3 kilowatts and below.

2. The second method is the triangle (△) connection method, that is, the three-phase stator windings are connected in a corresponding manner, the first end of the first phase winding is connected to the tail end of the third phase winding, which can be regarded as the U phase, the first end of the second winding is connected to the tail end of the first winding, which can be the V phase, and the first end of the third winding is connected to the tail end of the second winding, which can be the W phase. The three-phase AC power supply of UVW is connected to run respectively, which is suitable for three-phase asynchronous induction motors of 4kw and above. However, the wiring method of the motor should be based on the actual nameplate wiring.

Previous article:How to judge whether a three-phase motor is good or bad when it is powered on but does not rotate or respond?

Next article:Causes and solutions for one wire failure in three-phase motor

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Sound Level Meter MASTECH MS6700 Disassembly Pictures and Information

- Design of Multi-channel Data Acquisition System Based on CPLD

- EEWORLD University Hall----Underactuated Robotics MIT 2019 spring 6.382

- It's so tiring to work under a fool!

- Could you please tell me what glue is used to stick piezoelectric ceramic sheets to ultrasonic sensors?

- EEWORLD University Hall----C2000 series new products bring convenience to servo and motor drive systems

- [GD32E231 DIY Contest] 01. GD32E231-start and creative content introduction

- Wireless positioning principle: TOA&AOA

- MKL26 accelerator debug error, which god can help me take a look

- Old Iron

Cadence System-Level Package Design (Wang Hui)

Cadence System-Level Package Design (Wang Hui) Cadence System-in-Package Design Allegro SiPAPD Design Guide

Cadence System-in-Package Design Allegro SiPAPD Design Guide

京公网安备 11010802033920号

京公网安备 11010802033920号