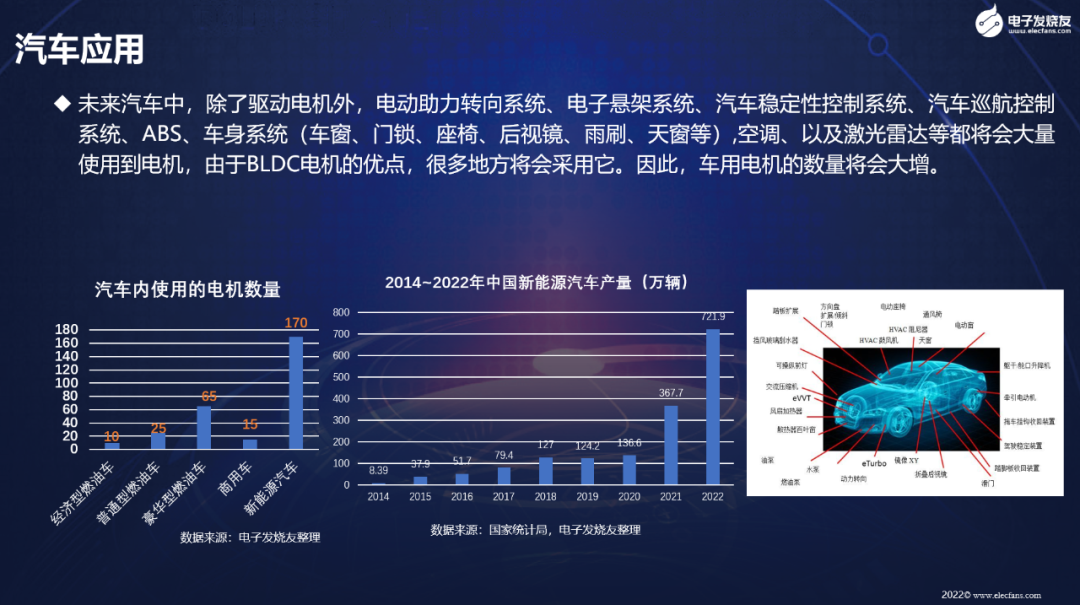

With the development of automobile electrification and intelligence, the number of motors used in automobiles will also increase rapidly. Some new energy vehicles even use more than 200 motors. Some listeners expressed doubts after listening to this, saying that it is possible to use so many motors in a car. Today, we will sort out and see where the motors in cars are used.

Whether it is a fuel vehicle or a new energy vehicle that has developed rapidly in recent years, the use of motors in vehicles is increasing rapidly, driven by key factors such as reducing vehicle weight, improving safety, reliability and comfort. In electric vehicles, the systems that were previously driven by the internal combustion engine energy transmitted by belts in fuel vehicles, and the subsystems driven by the hydraulic system, are now gradually being driven by motors, such as air conditioning compressors, water/oil/coolant pumps, fans, blowers, turbochargers, etc. Specifically, the motors on the car are mainly distributed in the fields of closed systems, powertrain systems, engines, smart cockpits, steering and chassis, thermal management, and vision.

Motors for closed systems

The closing system in a car requires many motors, including electric window drive motors, electric sunroof drive motors, electric tailgate pillar drive motors, electric tailgate latch motors, car door lock gear motors, door auxiliary closing motors, and hidden door handle pop-up motors, etc.

There is one window drive motor for each window, so four are needed, one electric sunroof drive motor, two tailgate pillar drive motors, one electric tailgate latch motor, four door lock gear motors and four hidden door handle pop-up motors, so 16 motors are needed here.

At present, the motors used in closed systems are basically DC brushed motors.

Electric motors for powertrain

The powertrain system includes high-torque motors for automatic manual transmissions, motors for hydraulic pumps in dual-clutch transmissions, and electronic parking locks. These motors are mainly used in fuel vehicles, and the only motor used in electric vehicles is the electronic parking lock motor. Some suppliers of motors in this system have begun to use brushless DC motors.

Electric motors used in engines

In order to cope with the increasing requirements of fuel economy and emission reduction, while meeting the improvement of vehicle performance and driving experience, fuel vehicles generally use engine management applications such as turbochargers, fuel pumps, electronic throttle control, exhaust gas recirculation, and exhaust after-treatment. This will use turbocharger motors, electronic throttle control motors, automotive exhaust emission control motors, high-torque turbine exhaust gate drive motors, eVVT cam phase actuator motors, and exhaust treatment fluid metering motors.

In addition to these, fuel pumps, air pumps, electric coolant pumps and other pump products, as well as cooling fan motors, are also used in fuel vehicle engines.

For electric vehicles, the most important thing is the main drive motor. Most small pure electric vehicles are driven by a single motor, the one installed in the front is called front drive, and the one in the back is called rear drive; there are also dual-motor drives with higher configurations, generally one in the front and one in the back, and all four wheels are drive wheels. This drive method is called full drive; higher configurations will use three drive motors, such as SAIC Roewe's Mavel X, Tesla's high-end version Model S Plaid, etc.; there are also four-motor drives with a motor installed on each wheel, also called hub motors, such as BYD's newly released high-end electric car Yangwang U8, etc. There are also some electric vehicles used for racing that use more main drive motors to provide powerful power. For example, the Ford Mustang Mach-E 1400 uses 7 motors in the front, three in the back, and four in the back, with a total output horsepower of more than 1,400 horsepower.

Motors used in smart cockpits

There are also many motors used in the smart cockpit, which include the tilt, height, front and rear adjustment of the front/rear seats, headrest adjustment, lumbar support, etc.; it also includes the human-machine interface in the cockpit, the lowering and folding of the in-car screen terminal, touch screens, car seats, steering wheels and tactile feedback of the accelerator pedal, etc.

In economy cars, electric motors provide convenient fore/aft adjustment and backrest tilt. In premium cars, electric motors control height adjustment, bottom cushion tilt, lumbar support, headrest adjustment, and cushion firmness. Other seat functions that use motors include power seat folding and power stowage of the rear seats. Higher-end models have fans installed in the seats to provide seat ventilation and heat distribution, and even massage functions.

Therefore, the smart cockpit will use seat belt pretensioner motors, electric seat adjustment motors, driver warning actuator motors, headrest adjustment motors, screen folding motors, etc. As for the quantity, there are 5 seat belt pretensioner motors, 1 warning actuator motor, 2 headrest adjustment motors, 2 screen folding motors, 2 to 10 electric seat adjustment motors, and 1 touch screen vibration motor, so about 5 to 21 are needed here.

Steering and chassis motors

In automotive steering and chassis applications, steering column adjustment motors, electronic parking brake motors, brake booster motors, electric power steering (EPS) motors, automotive electronic stability control systems (ESC) motors, anti-lock braking systems (ABS) motors, pedal adjuster motors, etc. are used.

Among them, EPS is a relatively important system in a car. The motor in it is used to supplement or replace the traditional hydraulic system to generate auxiliary torque to help the driver guide the wheels to rotate. Unlike most motors, the EPS system operates at a lower speed and needs to generate very precise torque and control near zero speed.

Electric brake boosters are designed to reduce the pedal pressure required to brake. They are increasingly used by automakers to improve driver comfort and passenger safety. These electric brake boosters use a dedicated electronic system to process the signal from the brake pedal and operate the master cylinder through a brushless DC (BLDC) motor, which must have a rugged design, fast response and sufficient reliability.

Electric Motors in Thermal Management Applications

The increasing demand for fuel economy and reduced emissions, as well as the rapid growth of hybrid and electric vehicles, has driven the need for more efficient and smarter cooling systems. Solutions such as primary engine cooling, battery cooling, cabin heating are also changing, and recently active grille shutters have been more widely used because they can warm up the engine faster and reduce vehicle drag at higher speeds.

In thermal management, electric coolant pumps, engine cooling fans, air conditioning fans, air conditioning compressors, car grid actuators, etc. are generally used.

Motors in Vision Applications

Vision applications include automotive lighting, mirrors, sensors such as cameras, etc. Windshield wipers are perhaps the most common example of an electric motor application in today's cars. Every car has at least one wiper motor for the front wipers. Rear window wipers are becoming increasingly popular in SUVs and hatchbacks, which means that rear wipers and corresponding motors are present on most cars.

A motor is also needed to deliver washer fluid to the windshield pump and, in some high-end cars, a headlight washer pump. If LED headlights are used, a cooling fan is also required.

Of course, the rearview mirrors of many cars can now be adjusted electrically, so two rearview mirrors require at least two motors, or even more.

Today's cars use more and more sensors, such as cameras, lidar, millimeter-wave radar, etc. These sensors also need to be driven by motors, so some motors will also be used.

Conclusion

Depending on the different configurations of the car, the number of motors used in the car ranges from 10 to 200. Calculated at 30 to 50 yuan per motor, for example, the average price of a general seat adjustment motor is 40 to 50 yuan, and an EPS motor is about 200 yuan. The value of the motor in the car is between 300 and 10,000 yuan. Add to that components such as the gear transmission system actuator and controller, and the value of the motor will double.

Previous article:Research on the application of data security in the field of intelligent connected vehicles

Next article:Five elements to realize software-defined cars

- Popular Resources

- Popular amplifiers

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- Rambus Launches Industry's First HBM 4 Controller IP: What Are the Technical Details Behind It?

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- STM32F401CC spi flash recognition problem

- [Raspberry Pi 4B Review] + Building an OPENCV Environment

- [2022 Digi-Key Innovation Design Competition] ESP32S2 button control RGB light

- New wearable technology developed, more skin-friendly and stronger

- Schematic diagram - What is the significance of the position of the energy storage capacitor in the figure?

- A collection of autonomous driving technical materials, download now without any points!

- Switch OUT?! Nintendo's latest recruitment may be aimed at the next generation console

- 【ST NUCLEO-H743ZI Review】+ 3. Key input

- Today's Live Broadcast | Outlook for DLP Technology in AR HUD and In-Vehicle Display Applications

- Welcome to join the power management section

Motor Control and Learning (Markus Latash, Francis Lestienne)

Motor Control and Learning (Markus Latash, Francis Lestienne) Unmanned Toy Car Collaborative Tracking - Dual Cars! Start + Ultrasonic Distance Measurement

Unmanned Toy Car Collaborative Tracking - Dual Cars! Start + Ultrasonic Distance Measurement

京公网安备 11010802033920号

京公网安备 11010802033920号