The 1151 pressure transmitter allows the two pressures of the measured medium to pass into the high and low pressure chambers, acting on the isolation diaphragms on both sides of the delta element (i.e., sensitive element), and is transmitted to the two sides of the pre-tensioned measuring wax sheet through the diaphragm and the filling liquid in the delta element. The measuring diaphragm and the electrodes on the insulators on both sides each form a capacitor. When no pressure is passed or the two pressures are equal, the measuring diaphragm is in the middle position, and the capacitance of the two capacitors on both sides is equal. When the pressures on both sides are inconsistent, the measuring diaphragm is displaced, and the displacement is proportional to the pressure difference, so the capacitance on both sides is not equal. Through detection, amplification and conversion into a 4-2OmA two-wire current signal.

What is a two-wire transmitter?

4~20mA two-wire transmitter refers to a transmitter powered by an intelligent transmitter or DCS card. Most of these transmitters are imported or assembled with imported technology. Their minimum working voltage is DC12V. The power supply voltage of DCS cards is DC24V. Zener safety labels with low internal resistance must be selected. At present, some DCS power supply cards of foreign companies have a current limiting resistor in series or a current limiting circuit (such as TDC3000 of HONEYWELL Company, with a resistance value of about 140~180Ω).

In industry, it is generally necessary to measure various non-electrical physical quantities, such as temperature, pressure, speed, angle, etc. In addition, electrical physical quantities (abbreviated as electrical quantities), such as current, voltage, power, frequency, etc., need to be converted into standard analog electrical signals before they can be transmitted to a control room or display device hundreds of meters away.

1151 Two-wire Transmitter Calibration Adjustment and Installation Experience

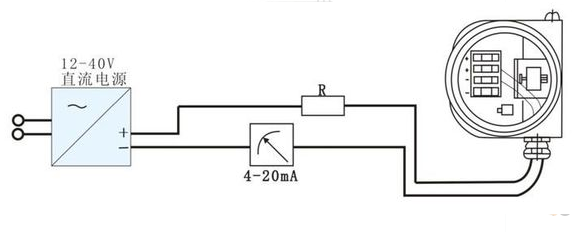

The commonly used 1151 transmitter is a two-wire instrument, and the power supply and signal share two wires. When wiring, unscrew the cover marked with "wiring", connect the two terminals marked with SIGNAL (signal) on the upper part to the power supply, and connect the two terminals marked with TEST (test) on the lower part to the ammeter with an internal resistance of less than 10, or you can leave it unconnected. To prevent the diode from burning out, the two test terminals can be short-circuited. Figure 3-21 shows the wiring diagram for instrument calibration. The power supply is generally 24V, but it can be adjusted within the range of 12-45V. If it is powered by 12V, it cannot carry a load, otherwise the transmitter will not work properly; if it is powered by 45V, it can carry a load of 1650. The power supply voltage cannot exceed 45V, otherwise the circuit will be damaged. When the power supply is 24V and the load is 500, the reading sensitivity is the highest.

The output signal of the 1151 transmitter can be measured with an ammeter or a digital voltmeter. Generally, a voltmeter is used. If an ammeter is used, it is easy to burn out if the wiring is wrong. When using a voltmeter, a 250 standard resistor R should be connected in the loop, and then the voltmeter should be connected to both ends of the resistor. After measuring the voltage, the current value can be calculated.

Connect the wires according to the wiring diagram. Introduce the pressure signal from the pressure inlet of the 1151 transmitter, read the instrument display value, and then calculate the error and hysteresis of the instrument to determine whether it is qualified or not. When the input differential pressure of the transmitter is zero, adjust the zero point screw to make the output current 4mA. Add the full range differential pressure signal to the transmitter, adjust the range screw to make the output current 20mA.

The zero point and range of the 1151 transmitter need to be adjusted repeatedly until the accuracy requirements are met. Then divide the transmitter differential pressure range into 5 equal parts, and input the corresponding differential pressure values point by point at 0, 25%, 50%, 75%, and 100%. The output current of the transmitter is 4mA, 8mA, 12mA, 16mA, and 20mA, and its error should be less than the basic error. If it exceeds the allowable range, the above items should be readjusted. If the linearity is unqualified, linear adjustment should be performed. The zero point, range, damping time, and migration adjustment methods and steps should be clarified to clarify the installation requirements and precautions of the 1151 capacitive transmitter.

1151 transmitter zero and span adjustment

The zero and range adjustment screws of the 1151 transmitter are located under the nameplate of the electrical housing. The letter Z is marked on the top of the zero screw, and the letter R is marked on the top of the range screw. The nameplate can be removed for adjustment. When adjusting the zero point, the range is not affected, but adjusting the range will affect the zero point, and the size of the zero point is 1/5 of the range adjustment. In order to compensate for this effect, the simplest method is to overshoot 25%. For example, the transmitter is required to have a range of 0 to 15.2kPa. Now when 0 is input, the output is 4mA; when 15.2kPa is input, the output is 19.8mA. By adjusting the range, the output is 19.8+ (20.0-19.8) × 1.25 = 20.05 (mA), that is, 0.05mA is adjusted more than the actual range, which is exactly 1/5 of the range increase of 20.05-19.8 = 0.25 (mA). In this way, the zero point is adjusted to 4mA, and the range is correct. There is mechanical backlash in the zero and span adjustments, and a dead zone will occur when changing the adjustment direction, so overshoot should be intentionally performed before reverse adjustment.

1151 transmitter zero migration

The adjustment method of zero migration is to change the position of the connector, which is on the side of the 1151 transmitter amplifier board component. When migrating the transmitter, first turn off the power of the instrument, unplug the board, and then change the position of the connector. The transmitter migration socket has three positions, the middle position is no migration, plugging in the letter E is negative migration, and plugging in the letter S is positive migration. Before leaving the factory, the manufacturer has adjusted the linearity of 1151 to the best position, so users generally do not need to adjust it easily. In case the linear error is too large, the adjustment method is as follows:

1. Input the middle value pressure of the measuring range and note the deviation between the theoretical value and the actual value of the output signal;

2. Multiply the range reduction coefficient by 6, and then multiply it by the recorded deviation. Range reduction coefficient = maximum range / adjustment range. For example, the maximum measurement range of the 1151 transmitter is 186.8kPa, and the actual use range is now 40kPa, that is, the range reduction coefficient is 186.8/40=4.67. When the input is 20kPa, the actual output current is 11.95mA, which is 0.05mA less than the theoretical value of 12mA. Therefore, when adjusting the linear potentiometer, the output should be increased by 0.05×6×4.67=1.4 (mA) at full scale, and then adjust the zero point and range until it meets the requirements. The linear adjustment potentiometer is on the welding surface of the amplifier board. Remove the back cover on the circuit board side to adjust it.

1151 transmitter damping time adjustment

The damping time adjustment is next to the linear adjustment potentiometer. Turning counterclockwise will reduce the damping time; turning clockwise will increase the damping time. The time constant of the transmitter filled with silicone oil in the 1151 transmitter diaphragm box is between 0.4-1.67s, and the time constant of the transmitter filled with fluorine oil is between 1.1-2.7s.

1151 Transmitter Installation Requirements

1. The installation of 1151 transmitters generally adopts the principle of "large dispersion and small concentration", and is arranged as close to the source components and convenient for maintenance as possible, or the installation location of the transmitter is selected within the range of 3 to 45 meters from the measuring point.

2. The installation site should avoid severe vibration and electromagnetic fields, there should be no corrosive media around, the ambient temperature should be less than 55, and the relative humidity should not exceed 80%.

3. When the measured medium is gas, in order to avoid measurement errors caused by condensate blocking the instrument tube or entering the 1151 transmitter, the transmitter should be installed at a place higher than the source component. For furnace negative pressure and condenser vacuum measurement, the transmitter is required to be installed at a place higher than the measuring point.

4. When the measured medium is liquid or steam, in order to avoid test errors caused by bubbles in the instrument pipeline, the 1151 transmitter should be installed below the source component.

5. For transmitters that require antifreeze and rain protection, they should be installed in an insulation box or a protection box. The conduit entry should be sealed, usually with a joint. The drain valve must be installed outside the box.

Precautions when installing the 1151 transmitter

1. The transmitter should not be installed in an environment with severe vibration, strong heat source nearby, or a large amount of corrosive media.

2. The pressure pipe of the transmitter should have sufficient diameter and the inner diameter should not be less than 8mm.

3. The pressure-conducting pipe of the transmitter should be as short as possible and have a certain inclination. It should not fluctuate to facilitate the removal of condensed water or gas. The inclination should not be less than 1:12.

Previous article:Why can't a DC separately excited motor be started directly?

Next article:Pressure transmitter zero drift and zero change

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

500 Cases of Electrical Maintenance of FANUC CNC Machine Tools

500 Cases of Electrical Maintenance of FANUC CNC Machine Tools Ericsson Radio School transmitter and receiver technology

Ericsson Radio School transmitter and receiver technology

京公网安备 11010802033920号

京公网安备 11010802033920号