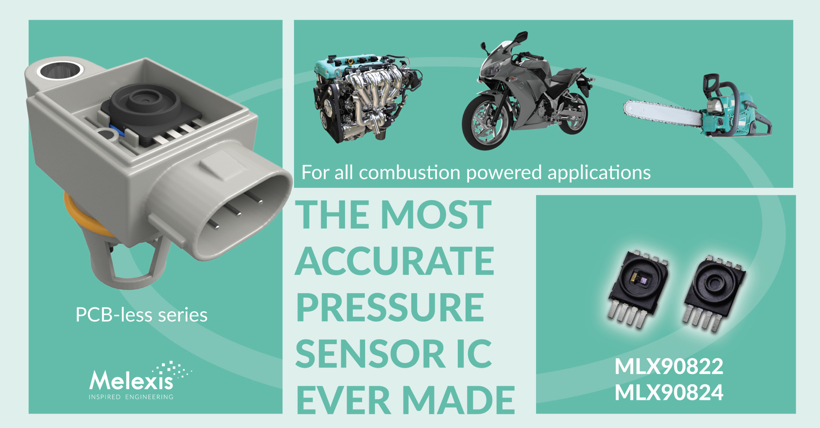

November 18, 2022, Tessenderlo, Belgium - Melexis, a global microelectronics engineering company, announces the launch of a new series of PCB-free pressure sensor chips. The chips in this series can maintain ultra-high accuracy throughout their entire service life. With this outstanding performance, the last generation of internal combustion engine (ICE) vehicles will become more environmentally friendly in all circumstances.

Pressure sensor application promotional image

Melexis, a global microelectronics engineering company, has launched a new series of integrated pressure sensor chips. This series of products is designed for automotive engine management. The MLX90824 measures absolute pressure and provides a digital output signal of the SENT protocol, while the MLX90822 provides an analog voltage output signal. These devices are factory calibrated and can measure full-scale pressures in the range of 1 bar to 4 bar.

Laurent Otte, Senior Product Line Manager at Melexis, explains why this product range helps customers: “The sensor chip in this range maintains an accuracy of +/-0.5% FS (Full Scale) over its entire service life. Thanks to the PCB-free package, the measurement accuracy is not affected by the integration of the sensor chip”. Extremely precise and stable pressure measurement helps optimize engine management to ensure fuel savings and reduced emissions.

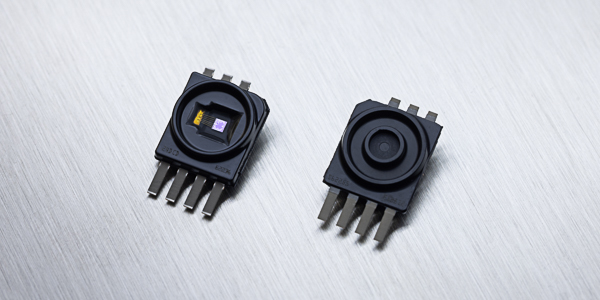

The MLX90824 and MLX90822 integrate sensors, signal processing circuits, SENT or analog output drivers, and all basic passive components. The MLX90824 (SENT output) provides a pre-calibrated negative temperature coefficient (NTC) thermistor input. Customers do not need to perform terminal calibration when connecting the NTC through the pressure sensor chip. Excellent overvoltage (+40 V) and reverse voltage (-40 V) protection mechanisms are integrated into the chip. With this wide protection range, trucks will be more energy-efficient and environmentally friendly. The operating temperature range of this series of pressure sensors is -40 ℃ to 160 ℃, and can even withstand temperatures up to 170 ℃ for a short time, supporting the trend of engine miniaturization.

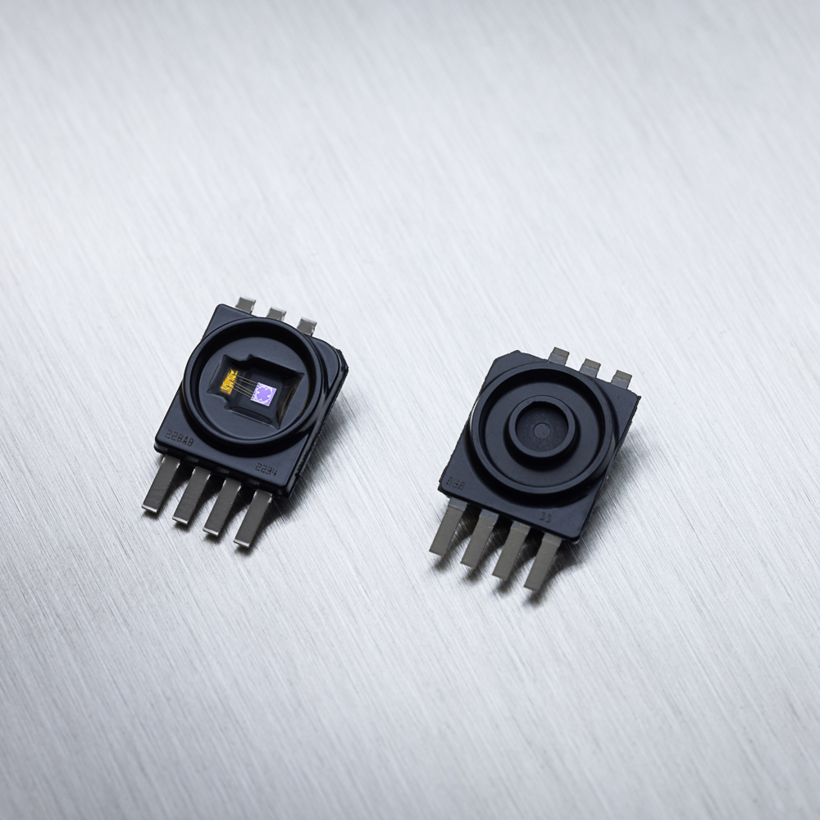

MLX90822 Product Image

The MEMS sensing element of the MLX90824 and MLX90822 consists of a micromechanical sensing membrane. The sensing membrane is bonded around a cavity etched in the silicon substrate. A reference vacuum is formed in the cavity. If the absolute pressure of the environment changes, the sensing membrane reacts. The piezoresistive elements implanted in the sensing membrane are connected to form a Wheatstone bridge to generate a signal. The onboard front-end electronics then amplify the signal and convert it into a digital signal. The 16-bit digital signal processing (DSP) is responsible for temperature compensation. Finally, the result is provided via the SENT output or analog output.

Both the MLX90824 and MLX90822 have been developed as Safety Element Out of Container (SEooC) in compliance with ISO 26262. The MLX90824 is ASIL B compliant and the MLX90822 is ASIL A compliant.

MLX90824_Product Image

“By acquiring stable and accurate pressure and temperature data, the engine can be managed optimally over the entire service life of the vehicle. This has a positive impact on fuel savings and emissions reduction,” said Karel Claesen, Product Manager for Pressure Sensors. “The MLX90824 and MLX90822 are optimized for the latest engine designs and new operating conditions.”

Last but not least, for motorcycles and other equipment with small engines, such as chain saws, lawn mowers, etc., the sensors must have very fast refresh rates and step responses. The MLX90822 output step response is 3 times faster than other pressure sensors previously launched by Melexis, which is enough to meet this requirement.

The MLX90824 and MLX90822 help OEMs continue to reduce emissions and combat rising fuel prices by lowering fuel consumption. The chips ensure that cars, trucks and motorcycles meet the latest stringent emissions standards.

For more information, visit www.melexis.com/MLX90824 and www.melexis.com/MLX90822 or contact us at sales@melexis.com.

Previous article:Detailed design plan of high-end vehicle domain controller

Next article:Deyi's micro-vehicle grade eMMC won the 2022 "China Chip" Award from the Ministry of Industry and Information Technology and has entered the Dongfeng Motor Group

- Popular Resources

- Popular amplifiers

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- How to use the VGA_SYNC_N signal in the VGA of DE1-SOC?

- CCS Tips: Remove the prompt when burning DSP/BIOS

- SEED-DEC6416 is available for purchase, second-hand is also acceptable

- Calculation of stack usage in C2000 DSP

- IRLR024 Output Current

- Bidirectional thyristor circuit wiring problem

- "Goodbye 2019, Hello 2020" + The wind and clouds are free and happy

- A simple question for help

- The power problem of the series resistance of the atomizer heating wire

- [GD32F310 Review] Interrupt test and GPIO usage

5512/BPA

5512/BPA

京公网安备 11010802033920号

京公网安备 11010802033920号