Achieving L4 and L5 autonomous driving has become the main goal of the automotive industry. To achieve this goal, the automotive electronic/electrical (E/E) architecture, software architecture, and communication architecture must be completely reconstructed. However, this has brought unprecedented challenges to wiring harness design.

To achieve the next generation of autonomous driving, OEMs have integrated more and more sensors into their vehicles, not only in quantity but also in resolution. Sensor manufacturers are making 15-megapixel cameras, wide-angle resolution radars, and high-frame-rate lidars. All of these require bulky and expensive wiring solutions to transmit data over long distances to electronic control units (ECUs) distributed in different locations within the vehicle.

Relevant data shows that the wiring harness is the third heaviest component in a car, weighing about 60 kg, second only to the chassis and engine, with a cable length of 5 km, and the wiring harness is the only automotive component that requires manual installation and production. In short, the space, weight and complexity of the wiring harness have reached their limits.

The global automotive wiring harness market is large and growing

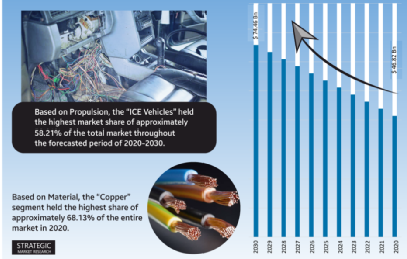

According to the forecast of Global Market Monitor, a data analysis agency, the global automotive wiring harness market will reach US$49.789 billion in 2025. In addition, Strategic Market Research also predicts that the automotive wiring harness market will reach US$74.46 billion in 2030, with a compound annual growth rate of approximately 4.75%.

Global automotive wiring harness market size 2020-2030 (USD billion)

The Asia-Pacific region will occupy the largest share of the global automotive wiring harness market (61.12%), followed by Europe; China, as the world's largest automobile manufacturer, has a rapidly growing market size.

The introduction of advanced technology systems in vehicles will drive the overall market growth. Among them, the upgrade of wiring harnesses will inevitably greatly promote the development of advanced driver assistance systems (ADAS) and autonomous driving, and the continued growth in global demand for electric vehicles will also drive the development of the automotive wiring harness market.

However, for reasons of fuel consumption, energy consumption, cost and environmental protection, the automotive industry must control the unlimited growth of the number of cables in the car without affecting the performance and bandwidth of the in-car connection. Obviously, this is an industry challenge that needs to be solved urgently.

The automotive industry is in urgent need of a standardized, state-of-the-art connectivity solution

There are two main types of in-car connections that make up the bulk of the wiring harness: symmetrical and asymmetrical. There is already a standardized protocol for symmetrical connections, such as ECU-to-ECU connections, which require the same bandwidth signal to be transmitted in both directions. This standard is the backbone infrastructure for automotive Ethernet, which is widely deployed in vehicles around the world.

Another major type of in-vehicle connection is an asymmetric connection, such as a sensor-to-ECU connection, which requires a large amount of data to be transmitted in one direction and only a small amount of data to be transmitted in the reverse direction. This type of connection has been implemented with proprietary bridge chips, such as Texas Instruments (TI)'s FPD-LINK and Maxim (acquired by ADI in 2021)'s GMSL. However, these technologies have encountered considerable difficulties in supporting the next generation of sensors and ECUs to achieve autonomous driving. Industry insiders said that the automotive industry is looking forward to having a standardized transmission scheme for such asymmetric transmission applications to simplify wiring harnesses.

To this end, the MIPI Alliance has provided a set of solutions. The MIPI Alliance is also the inventor of the CSI-2 and DSI-2 interfaces for automotive cameras, and has a deep understanding of automobiles. The organization released the MIPI A-PHY protocol in September 2020, which is aimed at transmitting high-speed data between cameras, radars, LiDARs and their related ECUs. This protocol is the first standardized, asymmetric, long-distance serializer/deserializer (SerDes) physical layer interface specification, especially targeted at solving ADAS and autonomous driving system (ADS) data transmission problems. It can be said that the MIPI A-PHY protocol provides an unprecedented breakthrough for automotive OEMs.

Recently, Valens Semiconductor released the VA7000 series chipset, which is the first MIPI A-PHY compliant chipset on the market, enabling long-distance, ultra-high-speed in-vehicle video connections. More than 30 Valens customers and partners are evaluating the chipset, including leading automotive OEMs and Tier 1s.

The excellent performance of the VA7000 chipset will help automotive OEMs enhance automotive ADAS capabilities and rewrite the status quo of software-defined vehicles. The VA7000 chipset has the following features:

High bandwidth: A single APHY link supports 8Gbps (deserializer output can support 32Gbps), and the next generation chip single link can support up to 16Gbps

Link distance: up to 15 meters (about 50 feet) for unprecedented architectural flexibility

Industry’s lowest bit error rate: highly immune to electromagnetic interference, with a packet error rate of 10E-19

Reduced total system cost: Ability to support low-cost unshielded cables and connectors

For the first time ever, the VA7000 chipset enables the industry to move away from the expensive and proprietary bridge CSI-2 extension solutions mentioned above, supporting standardized protocols based on digital signal processing (DSP) to simplify the connectivity infrastructure in the car. In addition, the addition of additional protocols (I2C, GPIO, and clock and frame synchronization) simultaneously enables high-bandwidth, latency-sensitive data to be transmitted to the central computer in real time.

VA7000 chipset unveiled at 2022 Detroit International Automotive Sensor Show

The automotive industry has strict requirements for handling electromagnetic interference. Valens' chips use three main mechanisms to resist the harsh automotive electromagnetic environment: PAM (pulse amplitude modulation), instant noise cancellation, and dynamic modulation. These mechanisms are very important to ensure strong electromagnetic compatibility of the chipset. Valens' A-PHY compatible chipset has a very low bit error rate. Converted into time, the bit error rate is only equivalent to one error in 10,000 years of link transmission. Such a bit error rate is several orders of magnitude lower than the solutions of peers.

A-PHY enters the automotive ecosystem to help realize high-level autonomous driving

A-PHY technology has been publicly endorsed by leading suppliers such as Mobileye, Sony, Denso, Aptiv, Omnivision, LG Innotek and Sunny Optical, and many others have already incorporated it into their product roadmaps.

The following are selected quotes from key industry leaders regarding MIPI A-PHY technology:

“We at Mobileye are working closely with Valens to ensure our next generation platforms are compliant with the MIPI A-PHY architecture.” - Amnon Shashua, Founder and CEO “We are excited to be the first to adopt this automotive connectivity standard. A-PHY will help Valens stay ahead of the curve.” - Kenji Onishi, General Manager of the Automotive Business Unit

“Denso prides itself on assembling the most cutting-edge technologies on the market, and we certainly consider A-PHY to be one of them. We are now evaluating A-PHY compatible chipsets to incorporate this technology into our products so that we can meet the needs of OEMs.” - Denso

A-PHY has also been adopted by the renowned IEEE standardization body as one of its standards. It is clear that the automotive ecosystem is converging around the MIPI A-PHY standard and A-PHY will soon become the first choice for global automotive OEMs.

There are many reasons why autonomous driving has not really arrived. Cost, safety, regulation, and ethics are all reasons that hinder the real implementation of autonomous driving. Another more hidden and important factor is the in-vehicle connection on the technical side. Since the development of autonomous driving, in-vehicle connection technology does not have enough bandwidth, link distance, and electromagnetic resilience to support the next generation of autonomous systems. However, the MIPI A-PHY standard solves these problems, and the Valens VA7000 chipset also provides the first A-PHY compliant solution on the market.

Previous article:Molex Automotive Connector Solutions | New Energy Battery Pack

Next article:In-vehicle gateway solution based on NXP i.MX8QXP

- Popular Resources

- Popular amplifiers

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- RSL10 rich board set!

- What challenges do you face in powering handling and harvesting robots? Let’s talk with Vicor engineers!

- What is the continuity threshold used for? Analysis of the wiring harness tester function

- Does DDR design require back drilling?

- [Integrated subway security control system based on Raspberry Pi 400] Material unboxing - Raspberry Pi 400

- SinA332.0 development board Linux & Qt adjust VGA resolution to 1280x720

- Single chip microcomputer CPU card programming system main frequency setting

- Award-winning live broadcast: Microchip's trusted platform for the CryptoAuthentication family

- What is the Internet of Things? What is the concept of the Internet of Things?

- DSP 2407 Book Request

LT1399IGN#TRPBF

LT1399IGN#TRPBF

京公网安备 11010802033920号

京公网安备 11010802033920号