The engine is the heart of the car, providing the most basic power for the car to run. Its quality characteristics are related to the car's power, economy, and environmental protection. Looking back at the development history of the automobile industry for more than 100 years, although the basic principles of the engine have not changed, aggressive automobile manufacturers often like to use the performance of the engine as a competitive highlight, and innovative design masters continue to integrate the latest technology into the engine, turning the engine into an increasingly complex mechatronic product. For example, the parameters that affect the engine calibration have increased to thousands.

•How to quickly and accurately find a few key parameters among many parameters?

•How can we set the parameters so that the fuel consumption, emissions, and smoothness meet the specified requirements at the same time?

•How to accurately locate and find the optimal design space in a broad parameter space in the shortest time?

•……

These are technical problems that the R&D and quality departments of many domestic automobile companies often encounter. Due to the lack of correct experimental design theory guidance, local automobile companies have high R&D costs, long R&D cycles, and poor R&D results. These situations restrict the company's upward space and even cause a considerable number of companies to fall into a vicious cycle of "declining sales → reducing R&D costs → continuing to decline sales → continuing to reduce R&D costs".

Judging from the successful experiences of well-known automobile companies in Europe, the United States, South Korea, Japan and other countries, experimental design is one of their magic weapons to maintain the competitiveness of their engines in the long term. This is in sharp contrast to the working style of their domestic counterparts who either rely on experience or hard work.

Experimental Design (DOE), also known as experimental design, is a scientific method based on probability theory and mathematical statistics to arrange experiments economically and scientifically, and to study and process the relationship between multiple factors and response variables. In the research of new engine products and new processes, experiments are usually required, and often many experiments are conducted. Experimenters always hope to extract useful information to the maximum extent possible from the fewest number of experiments, so they must design, analyze and optimize the experiments. Experimental design will tell engineers how to arrange experiments most reasonably, how to evaluate and test experimental results, and ultimately how to significantly shorten the R&D cycle, save money, and find the best product design parameters in the field of scientific research and process research. All analysis reports involving experimental design in this article are completed based on the professional statistical analysis software JMP.

Although experimental design is a cross-industry analytical methodology, its use in the automotive industry is also somewhat specific. Generally speaking, experimental design in the automotive industry can be divided into two categories: screening design and optimization design.

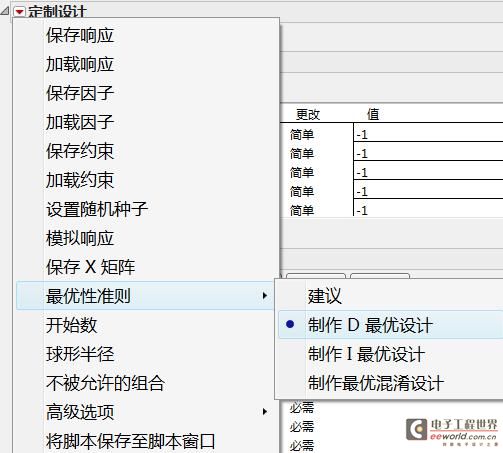

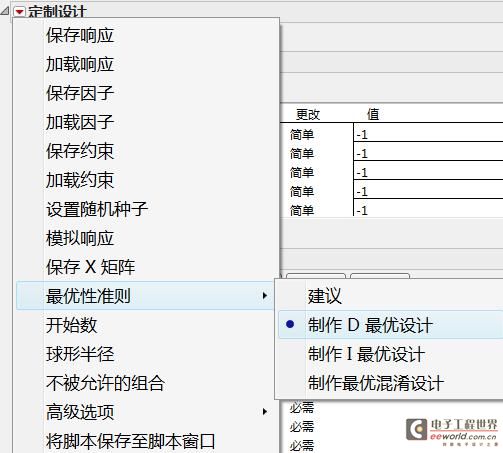

Screening design refers to how to effectively reduce the number of experiments on a large scale and accurately find a few key factors that affect engine performance when there are many potential candidate factors in the early stage of problem research. There are two specific means of implementation: one is the classic experimental design method, such as fractional factorial design, Plackett-Burman design, etc. (as shown in Figure 1); the other is the advanced experimental design method, such as D optimal design, etc. (as shown in Figure 2).

Figure 1

Figure II

The ultimate goal of screening design is to avoid guesswork and inefficient trial and error, and to quickly and accurately identify key parameters among many parameters, such as X5 and X8 shown in Figure 3.

Figure 3

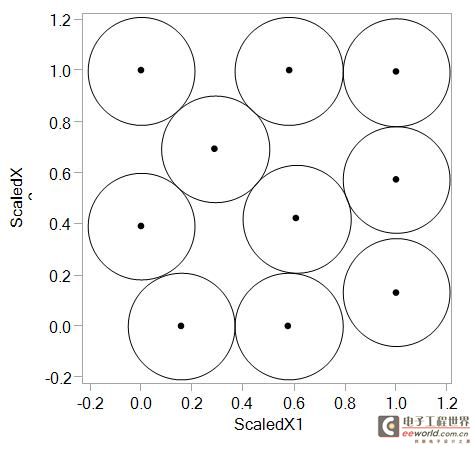

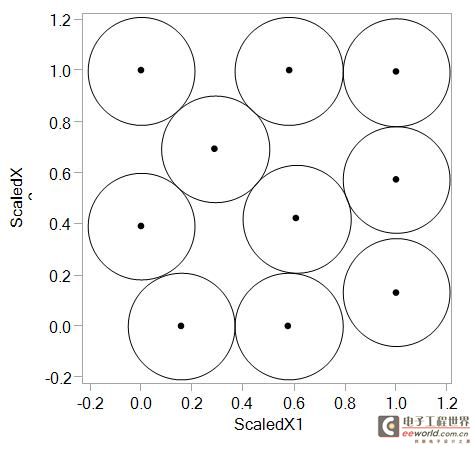

Optimization design means that in the middle and late stages of problem research, the key factors have been identified, but it is necessary to strive for excellence and accurately find the best design that maximizes engine performance in a limited experimental space. There are two specific means of implementation: one is the classic experimental design method, such as response surface design (as shown in Figure 4); the other is the advanced experimental design method, such as space filling design, I optimal design, etc. (as shown in Figure 5).

Figure 4

Figure 5

The ultimate goal of optimization design is to find the required parameter settings through a limited number of experiments instead of blindly debugging again and again, so that all indicators of the engine meet the specified requirements, thereby greatly reducing the R&D cycle and cost. The graph shown in Figure 6 is a prediction model that reflects the impact of the two key parameters of fuel pressure and valve train on fuel consumption, from which engineers can formulate the best process plan.

Figure 6

In short, flexible application of experimental design methods according to actual conditions can help R&D and quality management technicians quickly and effectively achieve the goal of screening variables and optimizing solutions, so that our cars have more powerful engines and our automobile industry can enter a higher stage of development as soon as possible.

Previous article:Development and supply and demand status of new energy vehicle power batteries at home and abroad

Next article:The latest progress in electric vehicle battery technology

- Popular Resources

- Popular amplifiers

Latest Automotive Electronics Articles

- Breaking through the intelligent competition, Changan Automobile opens the "God's perspective"

- The world's first fully digital chassis, looking forward to the debut of the U7 PHEV and EV versions

- Design of automotive LIN communication simulator based on Renesas MCU

- When will solid-state batteries become popular?

- Adding solid-state batteries, CATL wants to continue to be the "King of Ning"

- The agency predicts that my country's public electric vehicle charging piles will reach 3.6 million this year, accounting for nearly 70% of the world

- U.S. senators urge NHTSA to issue new vehicle safety rules

- Giants step up investment, accelerating the application of solid-state batteries

- Guangzhou Auto Show: End-to-end competition accelerates, autonomous driving fully impacts luxury...

MoreSelected Circuit Diagrams

MorePopular Articles

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

MoreDaily News

- Vicor high-performance power modules enable the development of low-altitude avionics and EVTOL

- Chuangshi Technology's first appearance at electronica 2024: accelerating the overseas expansion of domestic distributors

- Chuangshi Technology's first appearance at electronica 2024: accelerating the overseas expansion of domestic distributors

- "Cross-chip" quantum entanglement helps build more powerful quantum computing capabilities

- Ultrasound patch can continuously and noninvasively monitor blood pressure

- Ultrasound patch can continuously and noninvasively monitor blood pressure

- Europe's three largest chip giants re-examine their supply chains

- Europe's three largest chip giants re-examine their supply chains

- Breaking through the intelligent competition, Changan Automobile opens the "God's perspective"

- The world's first fully digital chassis, looking forward to the debut of the U7 PHEV and EV versions

Guess you like

- Lingdongwei MM32 series MDK5 project from 0 to 1

- SD8906A_600aA 1.5MHz Synchronous

- i.MX RT port of openmv

- CLUE badge

- TI C6000 interrupt process description

- Challenging tradition, new "wet" semiconductor equipment "beats" crystal equipment

- The I/O of this MCU is the kind that cannot be seen.

- The problem of interference between ADC channels of STM32

- Can't the RTC of MSP430F6723 use the internal clock REFOCLK?

- LPC1768CAN communication abnormality

BA3129FT1

BA3129FT1

京公网安备 11010802033920号

京公网安备 11010802033920号