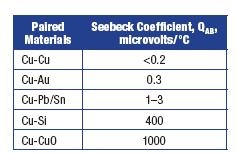

Thermal voltages or EMFs are the most common source of error in low voltage measurements [1]. These voltages are generated when different parts of a circuit are at different temperatures and when conductors made of different materials are connected together, as shown in Figure 5. The Seebeck [2] coefficients of various materials relative to copper are listed in the table.

Figure 5: Thermal voltages are generated when different parts of a circuit are at different temperatures and when conductors made of different materials are connected together.

The generation of thermal EMFs [3] can be minimized by making all conductors in the circuit out of the same metal. For example, a connection made with a crimped copper sleeve or lug to a copper wire creates a cold-welded copper-to-copper junction that generates very little thermal EMF. In addition, the connection must be kept clean and free of oxides. For example, the Seebeck coefficient for a clean Cu-Cu connection is ±0.2mV/°C, while the Seebeck coefficient for a Cu-CuO connection is as high as 1mV/°C.

Minimizing the temperature gradient in the circuit can also reduce the thermoelectric EMF. A technique to reduce this gradient is to keep all connection points as close as possible and to achieve good thermal coupling to a common, large heat sink.[4] Electrical insulation materials with high electrical conductivity must be used, but since most electrical insulators do not conduct heat well, specialized insulators such as hard anodized aluminum, beryllium oxide, specially filled epoxy, sapphire, or diamond must be used to connect each connection point to the heat sink.[5] In addition, allowing the test equipment to complete a warm-up period and reach thermal equilibrium at a constant ambient temperature can also minimize the effects of thermoelectric EMFs. Some instruments even provide various built-in measurement modes that change the polarity of the test signal to cancel the thermal EMF.

Keywords:Temperature

Reference address:What is the effect of temperature on nanomeasurements?

Figure 5: Thermal voltages are generated when different parts of a circuit are at different temperatures and when conductors made of different materials are connected together.

The generation of thermal EMFs [3] can be minimized by making all conductors in the circuit out of the same metal. For example, a connection made with a crimped copper sleeve or lug to a copper wire creates a cold-welded copper-to-copper junction that generates very little thermal EMF. In addition, the connection must be kept clean and free of oxides. For example, the Seebeck coefficient for a clean Cu-Cu connection is ±0.2mV/°C, while the Seebeck coefficient for a Cu-CuO connection is as high as 1mV/°C.

| Paired Material | Seebeck Coefficient, QAB, microvolts/°C |

| Cu-In | <0.2 |

| WITH their | 0.3 |

| Cu-Pb/Sn | 1–3 |

| with his | 400 |

| Cu-CuO | 1000 |

Minimizing the temperature gradient in the circuit can also reduce the thermoelectric EMF. A technique to reduce this gradient is to keep all connection points as close as possible and to achieve good thermal coupling to a common, large heat sink.[4] Electrical insulation materials with high electrical conductivity must be used, but since most electrical insulators do not conduct heat well, specialized insulators such as hard anodized aluminum, beryllium oxide, specially filled epoxy, sapphire, or diamond must be used to connect each connection point to the heat sink.[5] In addition, allowing the test equipment to complete a warm-up period and reach thermal equilibrium at a constant ambient temperature can also minimize the effects of thermoelectric EMFs. Some instruments even provide various built-in measurement modes that change the polarity of the test signal to cancel the thermal EMF.

Previous article:Case Study of Nano-Electrical Measurement I

Next article:The important role of shielding in nano-measurement

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- Difficulty in UHF reader design - anti-collision

- How to use MSP430 hardware I2C - Taking BH1710 and AT24C02 as examples

- Master the direct drive configuration of GaN devices in one article!

- Is it just a problem with the PCB backplane?

- [RISC-V MCU CH32V103 Review] Changing the PWM output channel to adjust the LED light

- MicroPython driver collection for X-NUCLEO-IKS01A3

- RT-Thread driver chapter: hwtimer reload value algorithm

- 【NUCLEO-L552ZE Review】+ Unboxing

- Convert ASC fonts for OLED display

- Do you really understand POE switches?

Follow me Season 2 Episode 1 All Codes

Follow me Season 2 Episode 1 All Codes ST BMS kit solution Battery management system overall solution

ST BMS kit solution Battery management system overall solution

京公网安备 11010802033920号

京公网安备 11010802033920号