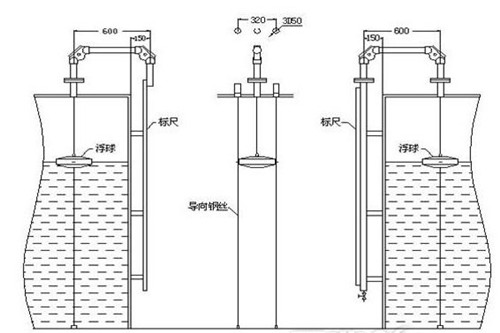

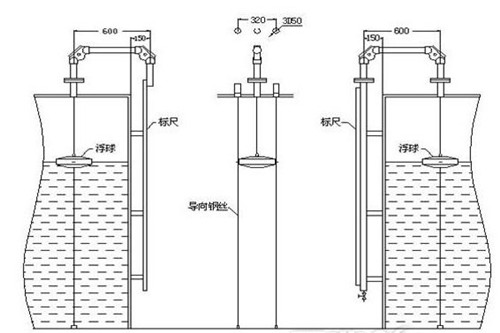

Compared with other liquid level measuring instruments, the structure of the float level gauge is relatively simple. The instrument measures the liquid level by a hammer needle plus a float. The liquid level data is finally obtained by the force exerted on the float in the liquid. This instrument system with simple structure and measurement principle is very suitable for measuring extreme media. When the liquid level rises, its overall force value will also change, which is the liquid level data of this force change; the float level gauge can be widely used in some important industries such as oil refining, sewage treatment, and papermaking. It has unique advantages in specific use environments, especially in measuring high-viscosity liquids, highly acidic and alkaline solutions with strong corrosiveness, and plays an important role. This article briefly introduces the characteristics of this instrument compared with other products:

First, the float level gauge has a simple structure. This is very important. Simple structure means simple operation. The simpler the operation, the more convenient it is for us to use. Moreover, a simple structure of a thing has a very good hidden advantage, that is, low cost and stable performance. Secondly,

during use, the instrument is very simple and easy to operate, its measurement principle is clear at a glance, and it is easier for operators to understand.

Third, long life. This point is believed to be deeply loved by all users, with a long service life and low cost. The float level gauge is resistant to strong corrosion. By selecting different materials for the measuring components, it can easily face various harsh measurement environments.

Fourth, it is easy to maintain. Generally speaking, the maintenance work of the float level gauge is very small. Under normal circumstances, it is enough to check the float, so it is very convenient to use and does not require too much after-sales service. When the float level gauge is in use, it can also measure the medium with high viscosity very accurately.

Although the principle of the float level gauge is simple, it is not simple to use, because using this method can obtain the most accurate data. When we are fixed at the origin, the float will be fixed at the origin, and there is a certain relaxation force. When the liquid level rises, the float level gauge will also begin to change. It flows up and down with the liquid level. It is combined with the hammer needle in the riser. When it reaches a certain position, it drives the magnetic flap. It uses the design of red on top and white on the bottom in the design of the float. The measurement results are very intuitive. For the convenience of measurement, a remote transmission device can be installed to achieve long-distance measurement and control of the liquid level.

Reference address:The advantages of a simple float level gauge in measuring extreme media

First, the float level gauge has a simple structure. This is very important. Simple structure means simple operation. The simpler the operation, the more convenient it is for us to use. Moreover, a simple structure of a thing has a very good hidden advantage, that is, low cost and stable performance. Secondly,

during use, the instrument is very simple and easy to operate, its measurement principle is clear at a glance, and it is easier for operators to understand.

Third, long life. This point is believed to be deeply loved by all users, with a long service life and low cost. The float level gauge is resistant to strong corrosion. By selecting different materials for the measuring components, it can easily face various harsh measurement environments.

Fourth, it is easy to maintain. Generally speaking, the maintenance work of the float level gauge is very small. Under normal circumstances, it is enough to check the float, so it is very convenient to use and does not require too much after-sales service. When the float level gauge is in use, it can also measure the medium with high viscosity very accurately.

Although the principle of the float level gauge is simple, it is not simple to use, because using this method can obtain the most accurate data. When we are fixed at the origin, the float will be fixed at the origin, and there is a certain relaxation force. When the liquid level rises, the float level gauge will also begin to change. It flows up and down with the liquid level. It is combined with the hammer needle in the riser. When it reaches a certain position, it drives the magnetic flap. It uses the design of red on top and white on the bottom in the design of the float. The measurement results are very intuitive. For the convenience of measurement, a remote transmission device can be installed to achieve long-distance measurement and control of the liquid level.

Previous article:Selection of valve types for side mounted magnetic flap level gauge interface installation

Next article:Improper installation of electromagnetic flowmeter sensor leads to decreased measurement accuracy and solutions

- Popular Resources

- Popular amplifiers

Latest Test Measurement Articles

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- Bicycle speedometer

- Orange pi GPIO output control, start from lighting

- People who work in software have more hair loss, will people who work in hardware be better?

- Huawei employee was sentenced for using company system bug to access confidential data without authorization; Huawei issued a letter of apology

- EEWorld Development Board Chip Coin is now open! Participate in the bidding to win a free order!

- What is the difference between SMT inductors and SMD inductors?

- Inside the DLP NIRscan Nano Evaluation Module

- How to process the current transformer signal with a single chip microcomputer

- 【2022 Digi-Key Innovation Design Competition】Material Unboxing

- Programmable linear constant current source circuit leakage current type: based on PAC chip GP8102, GP8202

TS358CDC3G

TS358CDC3G

京公网安备 11010802033920号

京公网安备 11010802033920号