Electromagnetic flowmeters are now widely used in industrial production, especially in the field of water flow measurement. Even many water companies use electromagnetic flowmeters to measure large-caliber water. This article is a case analysis of air conditioning chilled water measurement. The specific situation is as follows: An airport hotel obtains chilled water from the airport energy center for air conditioning. In winter, the chilled water is not used, and the shut-off valves on the chilled water pipes in and out of the hotel are closed, but the electromagnetic flowmeter indicates full scale.

Reference address:Case analysis of using electromagnetic flowmeter to measure air conditioning chilled water

(1) Cooling is stopped but the chilled water pipe is still full of water

(2) The adaptability of electromagnetic flowmeter to empty pipe

(3) Why does empty traffic flow occur?

The air conditioning chilled water system should normally be filled with water, but because the hotel was overhauling its equipment, the water was drained, and after the maintenance was completed, the valve was forgotten to be opened to let in water, resulting in an empty pipe.

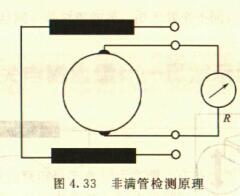

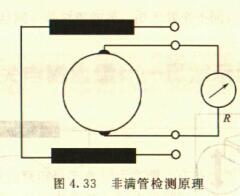

(1) Empty pipe detection and empty pipe zeroing

Electromagnetic Flowmeter

Where: Re—inter-electrode resistance;

But the resistance value is much larger than that in normal operation. Generally, the Re value to judge whether the pipe is empty is 3 times the resistance value in normal operation.

Where, qv—volume flow rate;

When the electromagnetic flowmeter is not full, the solution is generally to install an exhaust valve at the top of the upstream pipe of the flow measurement tube.

Previous article:Realization of traceability technology for pressure transmitter of gas flow standard device

Next article:Summary of common fault analysis and troubleshooting methods of sewage flow meter

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- MM32F103 BUG reminder to avoid pitfalls

- Will MakeCode support Python?

- What are the specific differences between triodes and MOS tubes?

- How to set the GND pin of a separate component as a flower pad in PADS?

- EEWORLD University Hall----Keithley 4200A-SCS parameter analyzer accelerates semiconductor equipment, materials and process development

- EEWORLD University Hall ---- Advanced C Language Programming for Embedded Systems (Ling Ming, Southeast University)

- Two-phase brushless DC motor speed control system based on DSP and CPLD

- The main structure of the DM642 image processing program

- Multi-way switch, battery inspection instrument

- EEWORLD University ---- Wildfire FPGA Video Tutorial

LTC6101ACS5#TRMPBF

LTC6101ACS5#TRMPBF

京公网安备 11010802033920号

京公网安备 11010802033920号