Homemade Electric Bike Fast Charger

Source: InternetPublisher:supremeOne Keywords: charger Updated: 2024/08/12

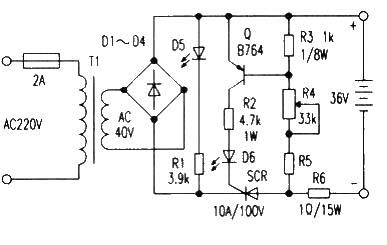

After repeated tests, the author has made a reliable electric bicycle fast charger. The circuit is shown in the attached figure.

1. Circuit characteristics

1. After the output voltage is set (for example, 36V), if the charged battery plate falls off and disconnects, causing a group of batteries to be blocked or a short circuit occurs, the battery terminal voltage will be reduced or zero, and the charger will have no output current.

2. If the charged battery voltage deviates from the set voltage, such as the set voltage is 36V, and a 24V, 12V, 6V battery is connected by mistake, the charger will also have no output current. If the setting is 24V and the battery is connected by mistake to a 36V battery, the charger output voltage is lower than the battery voltage, so the battery cannot be charged.

3. If the two output terminals of the charger are short-circuited, the trigger circuit of the thyristor SCR in the charger cannot work, so the thyristor does not conduct, and the output current is zero.

4. If the positive and negative poles of the battery are connected in reverse during use, the thyristor trigger circuit is reversely cut off, there is no trigger signal, the thyristor does not conduct, and the output current is zero.

5. Pulse charging is helpful to extend the battery life. Since low-voltage AC becomes pulsating DC after full-wave rectification, the thyristor will only conduct when its peak voltage is greater than the battery voltage. When the pulsating DC voltage is in the trough area, the thyristor is reverse biased and cut off, and stops charging the battery, so the pulsating DC flows through the battery.

6. Fast charging, automatic stop when fully charged. Since the voltage across the battery is low at the beginning of charging, the charging current is large. When the battery is about to be fully charged (the voltage at the end of a 36V battery can reach 44V), as the charging voltage is getting closer and closer to the peak value of the pulsating DC output voltage, the charging current will also become smaller and smaller, and automatically become a trickle charge. When the voltage across the battery is charged to the peak value of the rectifier output, the charging process stops. According to the test, three electric vehicle batteries of 36V (three 12V/12Ah batteries in series) can be fully charged in just a few hours using this charger.

7. The circuit is simple and easy to make, and almost no maintenance and repair is required.

2. Circuit Principle

The AC220V mains is stepped down by transformer T1, and after full-wave rectification by D1-D4, it is supplied to the charging circuit. When the output end is connected to the set battery to be charged according to the correct polarity, if the peak value of each half-wave of the rectified output pulsating voltage exceeds the output voltage of the battery, the thyristor SCR is triggered to conduct through the collector current of Q, and the current charges the battery through the thyristor. When the pulsating voltage is close to the battery voltage, the thyristor is turned off and charging stops. By adjusting R4, the conduction voltage of transistor Q can be adjusted. Generally, R4 can be adjusted from large to small until Q conduction can trigger the thyristor (conduction). In the figure, the light-emitting tube D5 is used as a power indicator, and D6 is used as a charging indicator.

3. Component Selection

The power transformer can use a BK200 control transformer with an output voltage of 36V, or a 4090 200V toroidal transformer with a secondary voltage of 22Vx2 or 20V×2 in series. The 4090 type toroidal transformer used by the author has three secondary voltages of 24Vx2, 12Vx2, and 0-6-23V. If the 24Vx2 gear is connected in series (48V), the output voltage is too high and the charging current is too large (when charging a 36V electric vehicle battery, the average charging current measured by the series ammeter is about 1.5-1.8A, which is the average value, and the peak current at this time can reach more than 5-7A). In order to reduce the output voltage of the transformer, the remaining 12V×2 and 0-6V coils are connected in series in the primary coil in the forward direction, so that the secondary output voltage is reduced to 40V when no load, and 36V when full load (when the average charging current is 1.2A), which can meet the use. Since the market price of the 4090 type toroidal transformer is only about 23 yuan, the production cost can be reduced. Enthusiasts can also wind the transformer by themselves.

In addition, the rectifier full bridge D1-D4 in the circuit can choose 8-10A square full bridge, with a circular mounting hole in the middle, which can be installed on an aluminum plate for heat dissipation. The thyristor can be a 1OA/100V gold-sealed unidirectional thyristor, which is fixed to the same heat dissipation aluminum plate with nuts as the rectifier bridge. The parameters of the trigger transistor Q are Vceo≥60V, IM=1A, and 2SB536, B564, B1008, B1015 or 2SA684, A720 and other tubes can be selected. R6 is used for current limiting protection. If the secondary output voltage of the transformer is appropriate and the charging current (average value) does not exceed 1.5A, this resistor can also be omitted. If

the charger is used to charge batteries of other voltages (such as 24V, 12V, etc.), the secondary output voltage of the transformer can be selected as 22V-26V, 12V-14V and other types, and the resistance values of R2 and R5 can be appropriately reduced. The band switch can also be used to control the secondary AC voltage and resistance conversion respectively, so that the charger has a wider range of use.

- Using Lead-acid Battery as Power Source for Walkman

- Practical and convenient fax machine power supply control circuit

- ISO113 circuit that can reduce power consumption

- Basic connection circuit of signal and power supply composed of ISOll3

- Use pulse width modulation to get a precise output voltage

- Simple and practical LED lamp driving circuit

- Boost drive circuit composed of RT8450

- Adjustable regulated power supply with current limiting protection

- LM317 regulated power supply

- How to Select Modular EMI Filters for AC-DC Converters

- Power circuit a composed of intelligent thyristor modules

- Voltage stabilization control circuit in power circuit

- 2-phase CPU power circuit using HIP6302 and HIP6601 chips

- FGDF-3 three-phase low-temperature iron-plated power supply circuit

- Single phase thyristor slotless nickel plated power circuit

- Simple charger circuit that stops when fully charged

- Simple and practical lithium battery charger diagram

- Motorola Model 888 Mobile Phone Charger

- Automatic constant current charger

- Charger using switching constant current circuit

京公网安备 11010802033920号

京公网安备 11010802033920号