Bypass capacitor welding analysis

Source: InternetPublisher:兰博 Keywords: bypass welding capacitor Updated: 2021/08/10

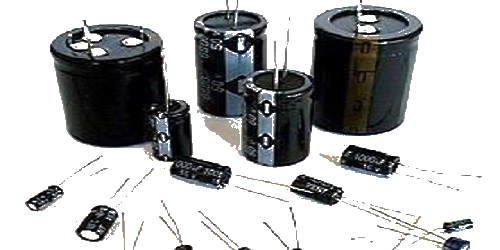

What is a capacitor? Where is the ideal welding position for a bypass capacitor? According to the comprehensive factors in the circuit, in addition to the ability of the bypass capacitor to reduce pulse current and stabilize the power supply voltage, what is more important is its capacitance, voltage value and Temperature rating for normal operation and where to place (solder) it in the board. Usually between VCC and ground, the capacitor's role is to provide a low impedance path so that AC power can pass through the DC circuit directly to ground. The capacitor also acts as an energy storage device, storing charge to stabilize voltage fluctuations caused by load changes.

Although capacitors can solve many circuit problems, incorrect capacitor selection or improper capacitor placement will cause the entire circuit to lose power, interfere with the current, or make it unstable. In addition to the normal operating rating, model, and size of the capacitor, engineers should pay close attention to the placement of the bypass capacitor in the circuit.

Ideal capacitor soldering position

To find the ideal location for capacitor placement, various factors must be considered, including the layout design of the entire development board, the functions of the chip or other components, the number of PCB board design layers, and the size of the circuit board, etc. Circuit board designers must be able to address the unique requirements for capacitors on each PCB board. Capacitors that are incorrectly selected or placed in the wrong location on the board often lead to unexpected problems or circuit failures. To ensure optimal performance of the entire board, here are the best practices for placing bypass capacitors on the board.

The ideal location for placing a bypass capacitor is as close as possible to the component's power pins. The purpose of this is to prevent components from being damaged by large currents in the circuit at the moment when the components are turned on and off. At the same time, the AC interference current is directed through a low impedance circuit to ground. If the capacitor is placed further away from the component's power pins, the additional trace length will create additional series inductance due to inductive effects, thereby reducing the self-inductance resonant frequency and useful bandwidth of the bypass capacitor.

In usual practical applications, there is always a certain distance between the power supply and circuit components (such as IC). Ideally, the copper trace between the IC and the power regulator is considered a zero-impedance trace. Of course, this is unlikely in reality. This line is not zero impedance. The resistance means that the voltage and current available from the power supply to the chip will be affected by this.

Copper traces in circuit boards, just like real wires, have certain resistance values and inductance effects. Compared with the resistance value, what should be more concerned about is the impact of the inductance effect of the copper traces in the circuit board on the entire circuit board, especially its huge impact on power transmission. When an IC or active device is powered on, this inductance effect will eliminate or slow down the impact of large current (peak current) from the power supply on the component.

Ideally, all copper traces on a circuit board should have no resistance or delay when current flows through them. However, in actual circuits, the inductance size is relative to the change rate of the current, which will prevent the current size from being quickly increased or decreased according to the equipment requirements. It has a delayed impact on the power-on and off processes, and the output signal waveform may also be distorted.

Generally speaking, the inductance effect becomes more pronounced the longer the length of the copper trace between the capacitor and the component pin, which will affect the resonant frequency of the capacitor, often resulting in a narrow bandwidth signal that cannot suppress all noise. So minimizing trace length reduces inductance, resistance and overall impedance.

Broadband frequency - multiple capacitor combinations

Different types of capacitors can suppress interference currents in specific frequency ranges, but for devices operating in a broadband frequency range, it is obviously unrealistic to expect a single capacitor to be able to meet the needs. The best solution is to parallel multiple capacitors for different bandwidth values at the same time. For example, a large capacitor will provide a low-impedance ground path for low frequencies, while a smaller capacitor will handle interference currents at higher frequencies.

With proper capacitor selection and placement, designers can provide suitable low-impedance paths for all frequencies of current flow. When laying out capacitor locations, it is best to arrange them in ascending order of capacitance value, starting with the capacitor with the smallest capacitance closest to the power pin. Then add larger capacitors in ascending order.

Compared with the slow charging and discharging speed of large capacitors, small capacitors charge and discharge faster and therefore respond quickly to high-frequency current signals. Since large capacitors require more time to charge and discharge, they cannot respond to high-frequency current signals in time. response, but works well at lower frequencies. Therefore, usually two types of capacitors, one large and one small, are used in parallel. For example, a 0.1uF capacitor is placed next to the power pin, followed by a 10uF capacitor.

Since the copper traces on the circuit board will produce impedance and inductance effects, the length of the copper traces should be reduced as much as possible, otherwise it will increase the overall impedance of the interference current signal. In the picture below, the capacitor can be placed under the SMT component, but on the other side of the entire circuit board. This method of placing it directly under the component is to shorten the length of the copper trace and reduce the inductance and impedance.

It's best to place the capacitor directly on the other side of the board from the power, ground pins, and other components such as the chip.

Placing the bypass capacitor on the other side of the circuit board relative to the components not only frees up excess space on the circuit board, leaving more space for board vias. And because the capacitor can be connected directly to the ground pin of the component, this also shortens the length of the ground line as much as possible.

For electronic devices with multiple power supply pins, each power supply pin must have at least one bypass capacitor connected to it. Although this electronic device will work with just one or two capacitors, it's a good idea to add at least one bypass capacitor to each power pin and keep the distance between the two as short as possible. This placement of bypass capacitors keeps the entire electronic device operating stably when the electronic device rapidly switches between different power outputs.

If the device operates over a wide frequency range, it is recommended to add multiple suitable parallel capacitors in ascending order.

ground

Designers should design the closest ground trace or pin trace to minimize inductance and make it easier for AC interference signals to be routed through the ground. An effective way to accomplish this is to reduce the impedance on the ground side of the bypass capacitor through shortened trace lengths or vias.

Summarize

Place the capacitor as close to the power pin of the electronic device as possible, which will reduce the inductive effect of the line between the two. When the power pin of the device requires multiple parallel capacitors, please solder the capacitors in ascending order (capacitance value), with the smallest capacitor closest to the power pin of the device.

Place the capacitor as far below the chip as possible, on the other side of the circuit board. When the trace distance is short enough, the other end of the capacitor can be connected directly to the ground pin of the device. If not, use the shortest trace or connect it directly to ground through a through hole.

in conclusion

The correct selection and use of bypass capacitors is the most effective way to reduce unnecessary interference signals in electronic circuits. Connecting the correct type of capacitor between the power and ground pins creates a low-impedance path for AC interference currents to ground. It also uses the charge and discharge function to prevent circuit voltage sag, suppress the generation of pulse current, and ensure that there is no interference current in the circuit.

In addition to the correct selection of capacitor type, the location of the capacitor in the circuit is critical to ensuring proper bypass operation. The best practice is to place the capacitor as close to the device's power pins as possible. The above is the ideal soldering position of the bypass capacitor, I hope it can help you.

- TPS274C65 helps reduce downtime and increase productivity in 24 VDC power distribution plants

- Fabrication of multi-cell lithium battery charging circuit

- Driving circuit of switching power supply field effect tube

- Brief Analysis of the Working Principle of AC Voltage Stabilizer Circuit

- Basic connection circuit of signal and power supply composed of ISOll3

- LED Driver ZD1680

- UC3842 Electric Vehicle Charger

- Production of backup power supply for cordless phone

- Detailed explanation of mobile phone charger circuit diagram

- Automatic charger made with LM3914

- Simulating bird call circuit schematic diagram

- STR5412 power circuit

- Power circuit b composed of intelligent thyristor modules

- Voltage stabilization control circuit in power circuit

- 2-phase CPU power supply circuit using HIP6302 and HIP6602 chips

- Computer motherboard power circuit with +5.1V, -5V, +12V and -12V outputs

- Lightning protection wiring of phase-shifting capacitor on pole a

- Simple dual-channel variable DC power supply circuit

- audio power circuit

- Capacitive dimmer switch circuit (1)

京公网安备 11010802033920号

京公网安备 11010802033920号