Which drugs can beat cancer? At what dose can we achieve the desired effect without side effects? Above what limit does an effective drug become toxic? Today, these questions can only be answered through batch tests using cell culture technology. They are undoubtedly an important method for medical research.

The CYRIS ®FLOX automatic detection system makes laboratory work easier. During the entire test process, the FAULHABER motor ensures that the culture medium has sufficient nutrients and drugs, and closely monitors the growth changes of cells, all without the need for the participation of experimental personnel.

The limit of vitality

Saving lives, curing diseases, relieving symptoms - advanced medicines benefit mankind day by day, year after year. But the day when there is no disease that cannot be cured is still a long way off. In addition, the COVID-19 pandemic has made us deeply aware of the harm caused by new diseases. Therefore, the research and development of new drugs cannot wait. It is best to ensure the efficacy and safety of these drugs before conducting clinical trials, because clinical trials are the crucial final stage. Because the efficacy of drugs is mainly reflected in human cells, we can judge them to a large extent through experiments. In other words, we can replace ordinary drug trials with cell culture technology.

"For example, we can determine the limit of a substance before it becomes toxic to cells," explains Márton Nagy, a biotechnology researcher at INCYTOИ ® in Munich. "This applies not only to pharmaceuticals, but also to potential environmental toxins. We add a certain amount of this substance to the nutrient solution used for cell culture and observe how the cells react. Then we continue to increase the amount. By taking specific measurements and observing under the microscope, we can determine the limit at which the substance becomes harmful to the cells. This value can be converted to a person's body weight. In practice, a tiny fraction of this dangerous value is set as the permissible dose limit." In the field of pharmaceutical research, many experiments are carried out on cancer cells. But the purpose of these experiments is exactly the opposite. Here, we want to find effective drugs and effective doses that can inhibit the proliferation of cancer cells or even completely kill them.

Observing the cells is a multi-shift, time-consuming process. On average, it takes about three days to conduct one experiment. During this phase, not only do many different measurements need to be performed, but the cells are also repeatedly photographed at short intervals. These consecutive pictures are combined to form a slow-motion movie showing the cell production process. The following three physical indicators need to be measured: oxygen content, pH value and monolayer cell transmembrane resistance.

Physical indicators provide us with information

The values of these parameters are affected by the cell's metabolism. For example, when affected by a drug's side effects, the cell consumes less oxygen than when in a healthy state. The pH changes in a very similar way: Since metabolism produces acidic substances, the cell's pH value generally decreases to the acidic range. If the decrease is smaller, it means that the metabolic process is affected. The degree of the decrease can be used to determine the impact of the drug. On the other hand, the resistance value is proportional to the number of cells. If the increase in resistance is delayed, it means that the cells are affected.

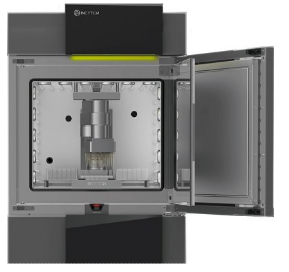

Until now, this type of test has required a lot of manual work. Only some of the different steps can be automated. The fully automatic CYRIS ®FLOX device developed by INCYTOИ ® not only completes the test process, which lasts for several days, without operator intervention, but also fully documents the test results.

At the heart of the test device is a microplate made of transparent material with 24 test wells. Cell samples are stored in these tiny culture dishes. A robotic arm with 24 pipettes adds nutrients and the substances to be tested to the culture medium. In the process, each pipette can suck up a solution with a different composition. Each test well is equipped with sensors for detecting oxygen content, pH value and resistance value. Through a microscope, photos can be taken from the bottom of the test well at regular intervals.

Automation R&D

INCYTOИ ® is a start-up with an academic background. The founders of the company worked as university researchers. Back then, they used motors from other manufacturers to build prototypes for the test equipment. Since they did not meet the application requirements, they were later replaced with FAULHABER motors. The new motors proved their quality with their compact design and reliable components. They also did not have to look for other drive products during the development process before going into series production. But they set new goals for this: "We wanted to use as few motor types as possible," says Development Manager Matthias Moll, describing the initial situation. "We also wanted a simpler wiring arrangement. We were looking for drives with integrated controllers. In previous machines, these were installed in the control unit of the robot arm, which resulted in a large number of cable connections on the moving parts." In addition, the motors should be able to report faults, for example, if overheating occurs, which could lead to or possibly cause a mechanical blockage.

The 2232…BX4 brushless servomotors in combination with the CxD series built-in motion controllers meet these new requirements set by INCYTOИ ® technicians. In addition, they are highly efficient, extremely compact, lightweight, small and suitable for laboratory applications. A total of six motors are installed in the CYRIS ®FLOX analysis device. Three of them are used to move the pipette head on the robot arm in three axes. Under their control, the pipette moves precisely above the microplate, then moves down to the position and releases the solution. The fourth motor drives 24 pipetting pistons that transfer 200 µl of culture solution into the sterile pipettes. The last two motors move the microscope on a positioning slide located below the cell sample. Due to the transparent material of the microplate, the sample can be photographed from below the test well with a microscope.

Precision and reliability in continuous operation mode

"In order to be able to observe the changes in the cells later in slow motion, the microscope head must be moved precisely to the specified position below the test hole," said Matthias Moll, describing the difficulty of completing this step. "With the FAULHABER motor, we can control the positioning accuracy of the slide to within two microns." We can make a vivid comparison: the thickness of a human hair is between 50 and 70 microns. The motor that drives the pipette tip piston must also have a high operating accuracy. In order to obtain valid test results, the amount of solution aspirated must be accurate.

For CYRIS ®FLOX, precision is a permanent mission. Repeatability is therefore paramount for motor applications. Operations that are frequently performed throughout the test phase must be repeated with pinpoint accuracy. "The drive must be able to guarantee the highest reliability in continuous operation mode," emphasizes the development manager. "Only in this way can we achieve longer 'walk-away time'." In today's era of laboratory automation, we use this term to refer to the time a test process can continue without human intervention. "With CYRIS ®FLOX, this time can be extended from a few minutes to several hours or even days. Our senior scientists and laboratory technicians can use their valuable time to complete other tasks. The increased efficiency of test operations and the reduction of operating costs also accelerate the return on investment of the equipment."

Company introduction: Drive technology experts from Schönaich, Germany

FAULHABER develops, produces and markets high-precision small and micro drive systems, servo components and drive electronics with a maximum output of 250 watts. This includes customer-specific, dedicated solutions as well as a full range of standardized products, such as brushless motors, DC micromotors, encoders and motion controllers. The FAULHABER brand is recognized worldwide as a symbol of high quality and reliability in complex and demanding applications such as medical technology, factory automation, precision optics, telecommunications, aerospace and robotics. From powerful DC motors with a continuous torque of 224 mNm to compact microdrives with an outer diameter of 1.9 mm, the FAULHABER standard series has more than 25 million combinations, providing the best drive system for specific applications. At the same time, this technical "construction combination" is also the basis for adjusting solutions, allowing us to set up various special versions to meet the specific needs of our customers.

Previous article:Pharmaceutical 4.0 with intelligent specification conversion

Next article:Qorvo® detects Delta and other circulating variants in two studies

Recommended ReadingLatest update time:2024-11-23 18:13

Recommended posts

- "bidirectional to out" error in Multisim

- Howtodealwiththeerrorshowninthepicture?

-

Multisim0000000

Training Edition

Training Edition

- iTOP-iMX6 development board-device tree kernel-default file configuration

- Thisdocumentmainlyexplainsthedefaultfileconfigurationofthedevicetreekernel(4.1.15)oftheiTOP-iMX6Q/D/PLUSdevelopmentboard. Herewetaketheqtsystemkernelcompilationofimx6q(similartoimx6dandplus)asanexample,thekerne

-

砂舞的玩笑

Embedded System

Embedded System

- A chart shows how 5G is better than 4G, with a challenge

- Theword"5G"isoftenencounteredthesedays,suchas"Huawei's5Gtechnologyisleading,andotherswillcatchupin2to3years","TrumpurgestheUnitedStatestostepup5G/6G",andyesterday's"MinistryofIndustryandInformationTechnology

-

灞波儿奔

Wireless Connectivity

Wireless Connectivity

- The problem with observed variables

- Code #includep16f877.inc __CONFIG(_CP_OFF&_WDT_OFF&_BODEN_OFF&_PWRTE_ON&_XT_OSC&_WRT_OFF&_LVP_OFF&_CPD_OFF); #definexxx0x55 yequ0x70 org0x0000 gotomain org0x20 main movlwxxx1 movwfy movlwxxx2 movwfy movlw17 movwfy

-

chenbingjy

Microchip MCU

Microchip MCU

- [K230 Embedded AI Development Board Review] + Code Recognition and Application

- Abarcodeisagraphicidentifierthatexpressesasetofinformationbyarrangingmultipleblackandwhitestripesofvaryingwidthsaccordingtocertaincodingrules.Commonbarcodesareparallellinesofblackandwhitestripeswithverydifferen

-

jinglixixi

Domestic Chip Exchange

Domestic Chip Exchange

- TARGET3001! Practical article - How to import Altium files into TARGET (with software installation package)

- Recently,afriendaskedmeifthesoftwareTARGET3001!canimportAltiumfiles,becausetheircompanyusesAltiumDesigner,andtheywanttoimportthepreviousprojectfilesinADdirectlyintoTARGET,whichwillsavealotoftimeandeffort.Thi

-

Target3001

PCB Design

PCB Design

- Popular Resources

- Popular amplifiers

-

Evaluation and analysis of shift quality of passenger car dual-clutch transmission based on AVL-DRIVE system

Evaluation and analysis of shift quality of passenger car dual-clutch transmission based on AVL-DRIVE system -

Characteristic Modes——Theory and Applications in Antenna Engineering

Characteristic Modes——Theory and Applications in Antenna Engineering -

ST BMS kit solution Battery management system overall solution

ST BMS kit solution Battery management system overall solution -

Chip Manufacturing: A Practical Tutorial on Semiconductor Process Technology (Sixth Edition)

Chip Manufacturing: A Practical Tutorial on Semiconductor Process Technology (Sixth Edition)

- Chen Han from Rouling Technology: Bringing small, flexible brain-computer interface sleep devices to every household

- Li Xiaojian of Weiling Medical: Brain-computer interface technology is opening a new era of integration of consciousness and AI

- Geng Dong of Jingyu Medical: Brain-computer interface DBS treatment technology has achieved domestic substitution

- Wang Changming from Capital Medical University: Digital therapy for epilepsy has entered the use stage

- Shi Chunbo of Qianqiu Intelligent: Using digital therapy to illuminate the light of children with autism

- Feng Shang, Digital Medicine Intelligence: ADHD digital therapy is providing more effective and convenient services for children with ADHD

- Ultrasound patch can continuously and noninvasively monitor blood pressure

- High-speed 3D bioprinter is available, using sound waves to accurately build cell structures in seconds

- [“Source” Observation Series] Application of Keithley in Particle Beam Detection Based on Perovskite System

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- STMicroelectronics discloses its 2027-2028 financial model and path to achieve its 2030 goals

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- How much does it cost to build a 5G base station? The total investment is staggering

- Motor electrical angle waveform acquisition

- Application skills/Chinese character display in single chip microcomputer system

- What is the difference between feedback and howling?

- Types of Motion Controllers

- Huada HC32A460 Series Introduction (I)

- MSP430F5529 IO port pin interrupt study notes

- The value of an electronics engineer

- When using RTT for recording data output, data loss is particularly serious. Does anyone know how to increase the RTT rate?

- Rockchip RK3399 announces system open source! Data integration and sharing!

Evaluation and analysis of shift quality of passenger car dual-clutch transmission based on AVL-DRIVE system

Evaluation and analysis of shift quality of passenger car dual-clutch transmission based on AVL-DRIVE system

京公网安备 11010802033920号

京公网安备 11010802033920号